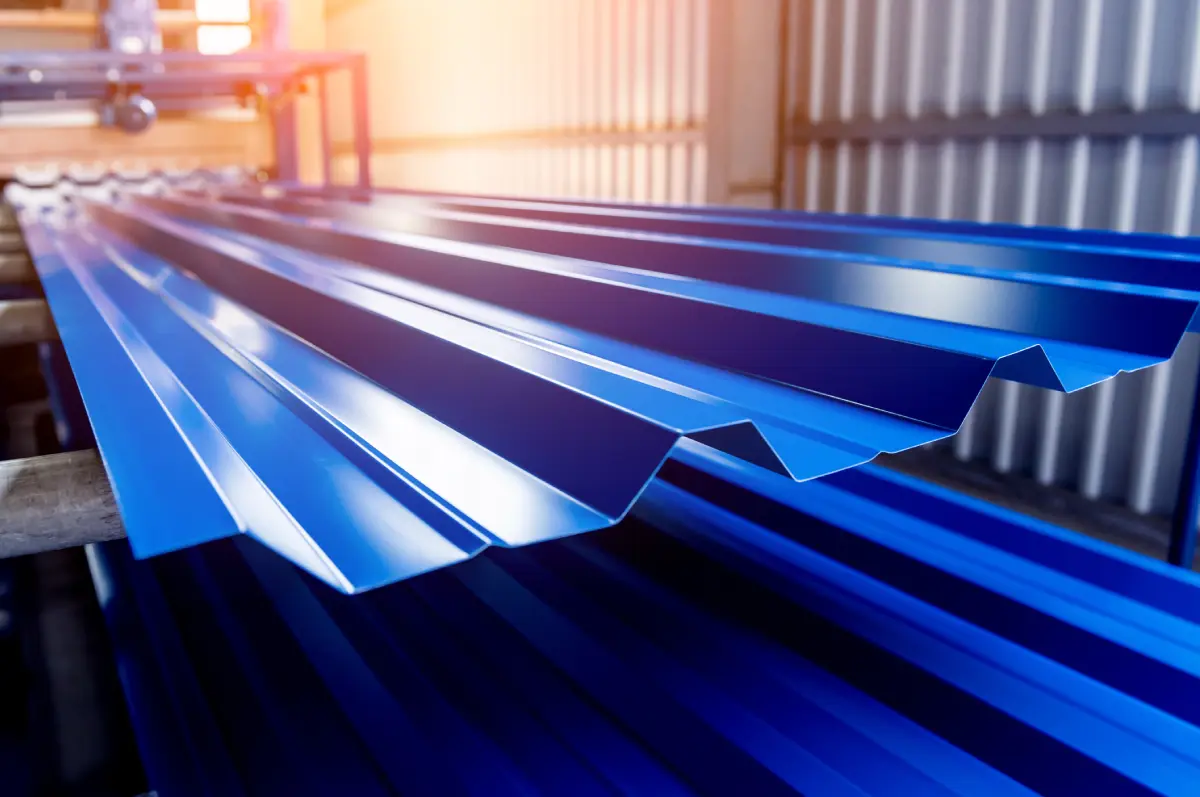

Powder coating is a successful coating solution used for products where robustness and corrosion protection are in high demand. Since it requires high temperatures (140-180 °C) to be applied, it is used for substrates that can withstand these temperatures – typically steel and aluminium.

Prized for its durability-enhancing qualities, powder coating is used to protect heavy machinery in the construction and automotive industries.

But this incredibly versatile solution also enhances the beauty and durability of a wide range of everyday items, from furniture to toys to kitchen appliances.

Powder coating doesn’t require solvents which means no volatile organic compounds (VOCs) are released. It is also highly resource-efficient since a small quantity goes a long way and the excess can be reused.

Powder coating is applied only in controlled industrial environments, ensuring that it is used safely and effectively.

Providing an extremely durable and resilient finish, powder coating helps metals remain intact and rust-free for decades, protecting against heavy usage, harsh environments and extreme weather.

Powder coating features a high transfer efficiency and low waste, while overspray can be reused. Its long lifespan contributes to its resource and cost efficiency.

Applied only in controlled industrial environments, the automated and highly regulated application of powder coatings ensures the protection of humans and the environment.

Powder coatings contain no solvents or biocides and their application to objects is also a solvent-free process. This means that no volatile organic compounds (VOCs) are released during application.

Once the colours are selected, the part is prepared and installed on the conveyor belt

Next the part undergoes either chemical or mechanical (blasting) pretreatment and cleaning

The powder coating is then applied with spray guns, either manually or automatically

Finally the applied powder is cured in the oven at an elevated temperature (typically 160-180°C)

The finished parts are then ready for immediate packing and shipping.

The renewable energy revolution relies on powder coating to maintain the performance and longevity of wind turbines, solar panels, and hydroelectric equipment.

Powder coating is used to create attractive products while helping them to withstand long-term use and temperature cycling as well as protecting electronic elements.

Sterile tools and surfaces are essential in the medical industry. Durable powder coatings keep medical equipment free of contaminants and biocompatible.

Thanks to their physical strength, corrosion resistance and aesthetic qualities, powder coated products are used to construct everything from building facades to stadiums.

Powder coating finishes are widely used throughout the automotive industry, providing a protective finish to automobile parts.

Powder coating protects outdoor equipment from environmental stress, providing a durable finish with formidable UV resistance that lasts through even the harshest conditions.

Polyesters are the most widely used powder coating and provide excellent value. They feature high flexibility and impact resistance, as well as very good UV-resistance and mechanical features.

Epoxies are extremely robust and feature exceptional hardness as well as the highest chemical and corrosion resistance.

Polyurethane coatings are known for their exceptional chemical and corrosion resistance, resulting in an extremely smooth and durable finish.

Epoxy-polyester powder coatings are used to decorate and protect a wide range of interior applications as they provide excellent adhesion, colour quality and ease of use.

Publication date

Dynamic field 1#

Abstract. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Download [PDF]

Publication date

Dynamic field 1#

Abstract. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Download [PDF]

Publication date

Dynamic field #1

Abstract. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Download [PDF]

Our social media campaigns raise awareness, engage stakeholders, and connect industries. The selection of campaign posts below provides an overview of our initiatives and highlights the essential role powder coating plays in key sectors across Europe. Explore our content to learn more about our work and stay connected for updates and information.

Our website uses analytics cookies. No sensitive personal data is involuntarily collected while you browse. Review our privacy and cookies policies here.